US Engranes Collinial Reducers – CBN Series

BN 3000 collinial reducers feature the latest in design and manufacturing technology, with the aim of providing an energy-efficient helical gear reducer combined with a variable or constant speed motor.

This is how this line of reducers have a 98% efficiency and due to their construction, they are stronger and more compact, which makes it a durable and quiet reducer.

Force One Speed Reducer – Worm Gear

FORCE ONE Worm Gear Speed Reducers have O-Rings on the input flange and cover of the output to prevent leaks more efficiently than a packing paper.

Our Worm Gear Motors have a hardened worm shaft to give greater durability than a forged worm shaft, a standard hollow bore, and optional shafts that can be integrated to offer you more flexibility and reduce inventory

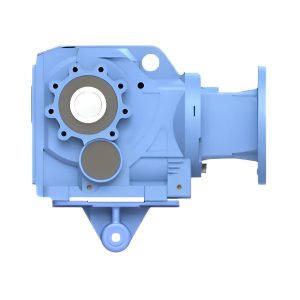

WorldWide Worm Gear Reducer – Aluminum

Worm Gear Reducers are one of the most used in the industry, thanks to their adaptability, design, and performance.

They represent the space-saving solution for simple applications in a low torque range as a result of their compact design and low weight.

They can be individually adapted to various drive situations due to the wide variety of output shafts and mounting options.

With input and output shafts made of solid machined and ground steel with keys and metric diameters.

WorldWide Worm Gear Reducer – FoFo Double Shaft

Worm Gear Reducers are one of the most used in the industry, thanks to their adaptability, design, and performance.

They represent the space-saving solution for simple applications in a low torque range as a result of their compact design and low weight.

They can be individually adapted to various drive situations due to the wide variety of output shafts and mounting options.

WorldWide Worm Gear Reducer – FoFo with Input and Output Shaft

Worm Gear Reducers are one of the most used in the industry, thanks to their adaptability, design, and performance.

They represent the space-saving solution for simple applications in a low torque range as a result of their compact design and low weight.

They can be individually adapted to various drive situations due to the wide variety of output shafts and mounting options.